Syria’s economic recovery gains pace with refugee returns and investor confidence

Syria’s economy is showing clear signs of recovery, with economic activity accelerating in recent months, the International Monetary Fund (IMF) said...

You may not think much about ammonia, but it plays a huge role in your life. It's a key ingredient in fertilisers that help grow nearly half the world's food. It could also be the future of clean energy. But the way we make ammonia today is dirty, outdated, and energy hungry.

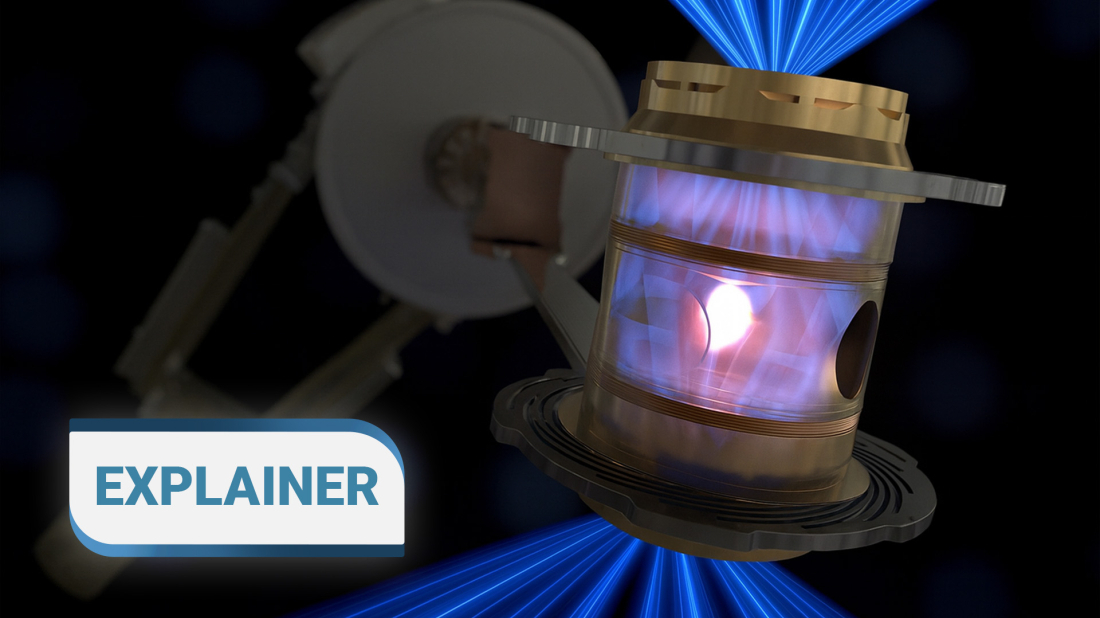

That’s where artificial lightning comes in.

A team of researchers at the University of Sydney has developed a new way to produce ammonia using electricity, essentially mimicking lightning in a box. It could be a breakthrough in our quest for 'green ammonia.'

Why do we need a new method?

For over a century, we’ve made ammonia using the Haber-Bosch process, a method developed in the early 1900s. It works, but there’s a problem: it’s incredibly energy-intensive and heavily dependent on fossil fuels.

About 90% of the world’s ammonia is made this way, and it accounts for nearly 2% of global carbon emissions.

“Industry’s appetite for ammonia is only growing,” said Professor PJ Cullen, lead researcher from the University of Sydney. “We need a low-cost, decentralised and scalable green alternative.”

Ammonia from thin air

The researchers have managed to create ammonia gas directly from air using electricity, no fossil fuels required.

Here’s how it works:

1. Plasma sparks the air

Electricity is used to excite nitrogen and oxygen molecules in the air. This creates plasma, an energetic state of matter, similar to the glow of lightning.

2. A special electrolyser does the rest

These excited molecules are passed through a membrane-based electrolyser (a shiny silver box, to be exact) that converts them into ammonia gas.

“In this research, we’ve successfully developed a method that allows air to be converted to ammonia in its gaseous form using electricity,” said Cullen. “A huge step towards our goals.”

Why gas form matters

Previous attempts by other labs produced ammonium in liquid form (NH₄⁺), which then required extra steps and more energy to convert into usable ammonia gas (NH₃). The Sydney team skips that step entirely.

By producing ammonia directly in gas form, their process is faster, simpler, and more energy efficient.

What’s so special about ammonia, anyway?

Besides fertilisers, ammonia has three hydrogen atoms—making it an ideal way to store and transport hydrogen. That’s a big deal for the clean energy transition.

Ammonia can be 'cracked' to release hydrogen, which can then be used in fuel cells, power plants, or even vehicles. It’s also being explored as a carbon-free marine fuel—a cleaner alternative for ships, which currently account for about 3% of global greenhouse gas emissions.

“Ammonia could be the missing link in the hydrogen economy,” says Cullen.

What comes next?

The plasma part of the process is already efficient and scalable. But there’s still work to be done on improving the electrolyser’s energy efficiency to make the entire system competitive with the traditional Haber-Bosch method.

“This new approach is a two-step process, namely combining plasma and electrolysis,” Cullen explained. “We’ve already made the plasma component viable. Now we need to push the efficiency of the electrolyser.”

Big impact, small footprint

The new method could allow ammonia to be produced locally—no need for massive industrial plants or long-distance transport. That means farmers in remote areas could one day generate their own fertiliser, and countries without access to cheap fossil fuels could still develop clean hydrogen industries.

It’s a promising step toward a decentralised, low-carbon future.

Final thoughts

This isn't science fiction, its science catching up to what nature has been doing all along - creating ammonia from lightning. With human-made plasma and smart engineering, we may finally have a cleaner way to grow food, fuel ships, and build a hydrogen-powered future.

As Professor Cullen puts it: “We’re excited to move from the lab to real-world impact. The spark is just the beginning.”

The Taliban in Kabul has rejected Russian claims that more than 23,000 militants from around 20 international terror groups are currently operating within Afghanistan.

Four years after Russia launched its full-scale invasion of Ukraine on 24 February 2022, the war is no longer defined by shock but by scale.

Seven people were killed after gunmen ambushed a police patrol in Kohat, a district in Pakistan’s north-west near the Afghan border, on Tuesday, in an attack that comes amid rising militant violence and heightened tensions between Pakistan and Afghanistan.

Four years into Russia’s invasion of Ukraine, the war can be measured not only in lives and territory, but in money. In Part One, the war’s cost was measured in casualties and kilometres. In Part Two, it is measured in billions of dollars.

The United Nations mission in Afghanistan said on Monday it had received “credible reports” that at least 13 civilians were killed and seven others injured in overnight Pakistani airstrikes inside Afghanistan.

New research suggests 40,000-year-old carved objects from south-western Germany bear repeated marks arranged in organised sign sequences similar to early proto-cuneiform, although they are not regarded as a form of writing.

The chief executive of Google DeepMind, Demis Hassabis, has called for more urgent research into the risks posed by artificial intelligence, warning that stronger safeguards are needed as systems become more advanced.

NASA successfully completed a critical fueling rehearsal on Thursday (19 February) for its giant moon rocket, Artemis II, after earlier hydrogen leaks disrupted preparations for the next crewed lunar mission. The launch is scheduled for 6 March, according to the latest information from NASA.

ByteDance will take steps to prevent the unauthorised use of intellectual property on its artificial intelligence (AI) video generator Seedance 2.0, the Chinese technology firm said on Monday.

The formation of a black hole can be quite a violent event, with a massive dying star blowing up and some of its remnants collapsing to form an exceptionally dense object with gravity so strong not even light can escape.

You can download the AnewZ application from Play Store and the App Store.

What is your opinion on this topic?

Leave the first comment